We are in the midst of an energy transition. How we produce and use energy will soon look completely different. Our relationship with the greenhouse gases released during the production process is also changing. Through our extensive network of pipelines, we enable the transport, storage and reuse of captured CO2.

By 2026 we want to offer initial capacity for transporting CO2. This is how we are helping implement our commitment to building a climate-neutral economy and society.

What is CO2?

CO2, the chemical formula for carbon dioxide, must be the most talked about chemical compound of our time. The excessive quantity of this greenhouse gas in our atmosphere is causing the earth to heat up. And yet CO2 is vital, for without it the earth would be unbearably cold. You could call it our planet's thermostat.

The properties of CO2

Greenhouse gases such as carbon dioxide trap the radiant heat from the sun, which is why we tend to view CO2 as a culprit in global warming. We associate it with fossil fuels and factories. While that's correct, it's not the full picture.

Long before humans started walking upright, CO2 was already floating around in our atmosphere. Without this greenhouse gas, fauna and flora – and therefore humans – could not thrive here. Plants, trees and algae need it to grow. They take in CO2 and convert it into oxygen (O2). This process is what created such a pleasant climate, with an atmosphere that is nicely balanced. Unfortunately things are different today.

Too much CO2 in our atmosphere

Although greenhouse gases such as CO2 account for only 0.04% of our atmosphere, they have an enormous impact on the global climate. Starting with the industrial revolution, we have been using massive quantities of fossil fuels such as coal, oil and natural gas.

That brought us enormous prosperity, but it also drove and continues to drive huge amounts of CO2 into the atmosphere. Today there is 51% more CO2 in our atmosphere than prior to the industrial revolution. In other words, we're pushing the Earth's thermostat higher and higher. Hence the urgent need for an energy transition that will enable us to drastically reduce CO2 emissions.

What is industry doing to reduce its CO2 emissions?

Companies are making enormous efforts to reduce their CO2 emissions. The energy transition is moving forward at top speed, but some processes cannot be adjusted so quickly. Fortunately, there is also a solution for this: CO2 capture, storage and, where possible, even reuse, or CCUS.

Transition towards a climate-neutral industry

40% of CO2 emissions in Belgium comes from our industrial sector, which is why companies are launching all kinds of initiatives and process innovations to reduce their CO2 emissions. These efforts include insulating buildings, upgrading machinery and equipment, optimising production processes and so on.

Installations and processes are being electrified. For heavy industrial processes, where there is not enough electricity, hydrogen is a good alternative.

And any CO2 that companies still emit can be captured and transported to sites for storage or reuse via our extensive network of pipelines.

CO2 emissions are increasingly expensive

Under the European Commission’s Fit For 55 plan, all 27 Member States are striving to reduce CO2 emissions by 55% by 2030. The ultimate goal is to achieve a CO2-neutral society by 2050. To achieve that goal, the European Union operates an Emissions Trading System for CO2.

For every tonne of CO2 that a company emits, it must buy one emission allowance. The number of emission allowances decreases every year, making it more and more expensive to pollute. For industrial companies, the emission allowances bill can amount to billions of euros per year. The result is that captured CO2 not only pursues an environmental goal, but is also financially encouraged.

How do we use our CO2 infrastructure to help companies reduce their emissions?

CO2 emissions must drop drastically. In addition to investing in renewable electricity from solar and wind power, industry is looking at the potential of hydrogen and CO2 capture. To make these developments possible, we at Fluxys are working hard to future-proof our network of pipelines.

Our ambition can be expressed in three numbers: 30x30x30. By 2030, we want to offer enough capacity to transport 30 million tonnes of CO2, the equivalent of removing 13 million cars from the road. By way of comparison, there are 5.9 million passenger cars on the road in Belgium. By 2030, we also want to offer companies the capacity to transport 30 TWh of hydrogen, an amount of energy that represents more than one third of total electricity consumption in Belgium.

A genuine underground movement

We are engaging with industry to adapt our existing infrastructure in a timely manner and to build new pipelines where necessary. To enable and accelerate companies' energy transition, we aim to develop hydrogen and CO2 pipelines for and between industry in Flanders and Wallonia.

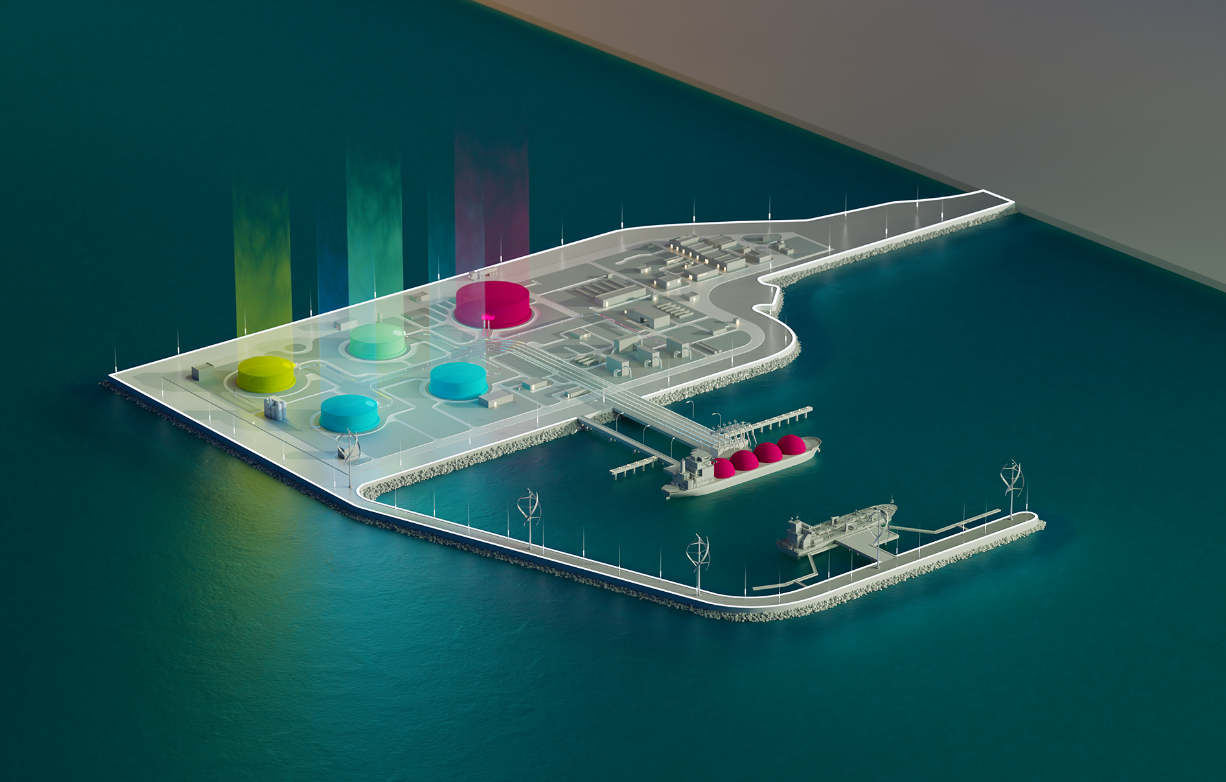

Today, we already have a highly meshed network of natural gas pipelines. This is evolving into a network that will also transport CO₂ and hydrogen, which is how we will make Belgium an import and transit country in Europe for molecules such as CO2 and hydrogen. Our terminals in Zeebrugge, Ghent and Antwerp will play a key role in achieving this ambition of becoming an import hub for hydrogen and an export point for CO2.

Our CO2 infrastructure projects

We are working on all kinds of initiatives and collaborations to develop our CO2 infrastructure. We are building new pipelines underground (onshore) and under the sea (offshore) and building terminals that temporarily store CO2 and load it onto ships for transport to permanent storage sites. We are also investing in projects to enable the reuse of CO2.

Subsea pipeline for large-scale decarbonisation

The energy transition, one of the greatest challenges facing humanity, requires united forces. We can't do it alone. For example, we are working with Norwegian energy company Equinor on a 1,000 km subsea pipeline between Zeebrugge and Norway. The CO2 is compressed at our terminal in Zeebrugge. We transport captured CO2 via the new pipeline from Belgium and neighbouring countries to Norway, where the CO2 is stored in underground aquifers or empty gas fields beneath the North Sea bed.

In 2025, we will begin operations to transport and store, by 2030, some 20 million to 40 million tonnes of CO2 per year. Those 40 million tonnes of CO2 are equal to the total emissions of Belgian industry. By combining our knowledge and experience we are taking another step towards meeting climate targets as a Belgian industry.

CO2 hubs in Antwerp and Ghent

At the ports of Antwerp and Ghent, we are building facilities that liquefy CO2, store it in buffer storage sites and export it by ship for storage in depleted gas fields deeper under the sea.

We are involved in a partnership with French company Air Liquide and Port of Antwerp-Bruges for the Antwerp@C CO2 Export Hub in Antwerp. Together we are building one of the world’s first and largest CO2 export facilities, with a capacity of 10 million tonnes of CO2 per year.

Ghent will be home to Ghent Carbon Hub, in collaboration with North Sea Port and steel producer ArcelorMittal. Ghent Carbon Hub will have the capacity to process 6 million tonnes of CO2 per year, corresponding to about 15% of total industrial CO2 emissions in Belgium.

CO2-negative building blocks

In addition to projects for the storage of CO2 (CCS) we are taking part in an initiative where we reuse CO2 (CCU). Belgian concrete company Orbix has developed a technology for making building blocks that contain no cement, but instead a combination of waste from the steel industry and CO2. We are working on this.

co2ncreat is a project in collaboration with Orbix, Lhoist and Prefer. Lime producer Lhoist captures CO2, which Fluxys transports to the plant operated by construction company Prefer. Prefer uses Orbix technology to make environmentally friendly building blocks, which means that Lhoist does not have to purchase increasingly expensive emission allowances. The use of CO2 in the production of building blocks is also avoided because no cement is needed. A win-win.

What is the decarbonisation potential for my business?

You and your company want to emit less, but how do you start? What steps should you take? Our experts will be happy to advise you on the challenges that the energy transition entails. Let's put our heads together and we’ll then incorporate your answers into our plans and refine our infrastructure map.

Nachrichten

-

Equinor, Fluxys and OGE join forces to develop cross-border CO₂ infrastructure from Germany to Norway via Belgium

-

Fluxys Chile and ENAP strengthen cooperation to advance hydrogen and derivatives infrastructure in Chile

-

Construction of CO₂ backbone started in Antwerp port area by joint initiative of Fluxys Belgium, Pipelink and Air Liquide